|

|

|

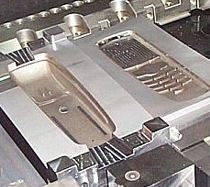

| Mold Development |

| |

|

|

| Precision and High Speed Machines For High Quality Mould-making |

|

| |

|

|

|

KM Mold is well known in making injection mold of camera, mobile phone, gears and other precision instruments. We made molds for SONY, Olympus, KYOCERA, Pextax, Nikon, etc.

KM Mold is committed to your project from design to mold completion. An effective moldmaking process is critical to achieving this goal. Our skilled workforce and leading edge technology allows us to construct molds to your specifications quickly and accurately. We produce a wide range of injection molds from single cavity SPI class 103 molds to multi-cavity SPI class 101 molds. Our molds types include standard molds with side actions and lifters, hot runner molds, unscrewing molds, and insert type overmolds. The majority of the molds we build range from 50 ton to 700 ton press size.

Our molds are constructed to precise DME and Hasco mold standards. Molds built for our US market are constructed using inch components. We can provide any required US brand name mold components such as Progressive, PCS, Parker, DME, and many others. We use high grade steel and other mold materials from companies such as Daido, Assab (Uddehom/Bohler), and Thyssen. Hot runner systems made by Husky, DME, Moldmaster, Synnventive, and Incoe are all available per your specification. |

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|